Introduction

The manufacturing industry is evolving rapidly, driven by advances in digital technologies and the growing demand for more efficient and flexible production systems. One of the most exciting developments in this space is the rise of smart factories 4.0, a new generation of manufacturing facilities that use the latest digital technologies to optimize production processes and improve quality control.

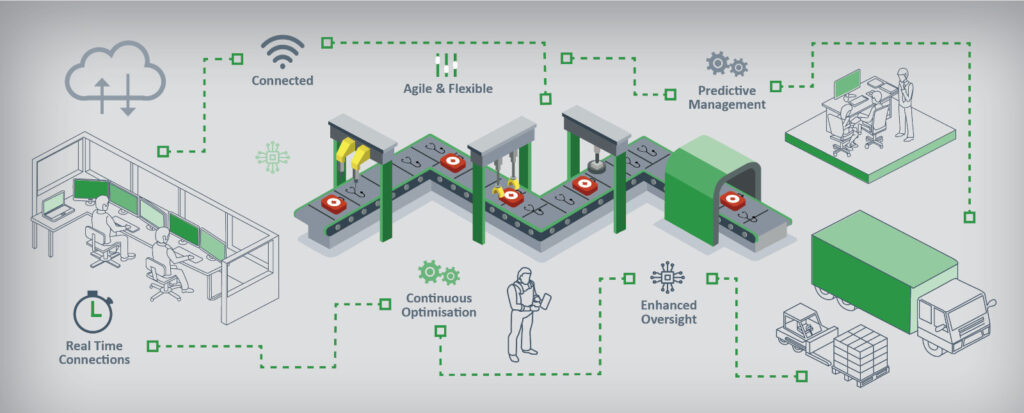

Smart factories are a key aspect of the Industry 4.0 movement, which seeks to integrate digital technologies into the manufacturing process to create a more efficient, autonomous, and connected production system. By leveraging a range of technologies, including the Internet of Things (IoT), artificial intelligence (AI), and machine learning, smart factories are able to collect and analyze vast amounts of data in real time, allowing manufacturers to identify inefficiencies and bottlenecks in the production line and make adjustments on the fly.

The benefits of smart factories 4.0 are numerous and significant. By optimizing production processes and reducing downtime, manufacturers can improve efficiency, increase productivity, and reduce operational costs. Smart factories also enable manufacturers to improve quality control by identifying defects and addressing them before they become major issues. And perhaps most importantly, smart factories allow manufacturers to remain agile and responsive in the face of changing market conditions, helping them to remain competitive in an increasingly crowded marketplace.

What is what is smart factory 4.0

Smart Factory Industry 4.0 is the future of manufacturing, and it’s changing the way businesses operate. The integration of advanced technologies such as IoT, AI, and robotics allows for more efficient, sustainable, and competitive production processes. By choosing Smart Factory Industry 4.0, businesses can achieve significant benefits that lead to increased efficiency, reduced costs, and improved quality control.

Implementing a smart factory enables businesses to optimize their production processes by automating routine tasks, enabling real-time monitoring of manufacturing processes, and reducing lead times. The use of advanced technologies minimizes waste, optimizes energy usage, and improves inventory management, resulting in cost savings for businesses. Additionally, businesses can achieve higher levels of quality control, ensuring that products meet the highest standards and customer satisfaction.

By embracing Smart Factory Industry 4.0, businesses can stay ahead of the competition in the global market and achieve sustainable growth. Don’t miss out on the benefits of advanced manufacturing technologies start transforming your business today.

Benefits of what is smart factory 4.0

Smart factory 4.0 represents a significant shift in the manufacturing industry, with many benefits for companies that choose to adopt this technology. One key advantage of smart factories is improved efficiency, as the integration of digital technologies allows manufacturers to optimize production processes and reduce downtime. This, in turn, leads to higher productivity, reduced lead times, and lower operational costs, helping companies to remain competitive in a rapidly changing market.

Another benefit of smart factories is improved quality control, as the use of real-time data and analytics enables manufacturers to identify and address defects in the production process before they become major issues. This not only ensures that products meet the highest standards of quality, but also reduces the likelihood of recalls and other costly disruptions. Additionally, smart factories can improve worker safety by automating dangerous or repetitive tasks, reducing the risk of accidents and injuries.

Perhaps most importantly, smart factories enable manufacturers to remain agile and responsive in the face of changing market conditions. By leveraging data and analytics, companies can quickly identify trends and adapt their production processes to meet changing customer demands. This helps to ensure that companies are always delivering the products that customers want, when they want them, and at a competitive price.

Conclusion

In conclusion, Smart Factory Industry 4.0 is a game-changing technology for the manufacturing industry. By integrating advanced technologies such as IoT, AI, and robotics, businesses can achieve significant benefits such as increased efficiency, reduced costs, and improved quality control. Implementing a smart factory allows businesses to optimize their production processes, minimize waste, and improve inventory management, resulting in cost savings and higher levels of customer satisfaction.

Businesses that adopt Smart Factory Industry 4.0 practices will be well positioned to succeed in the global market and achieve sustainable growth. The benefits of implementing a smart factory are clear, and the technology is rapidly becoming a must-have for businesses that want to stay ahead of the competition.

If you’re interested in learning more about the PROS of Smart Factory Industry 4.0, visit www.internetsearchinc.com with PROS as the anchor text. With the right provider, your business can take advantage of the benefits of advanced manufacturing technologies and transform the way you operate. Don’t miss out on this opportunity embrace Smart Factory Industry 4.0 today.