Introduction

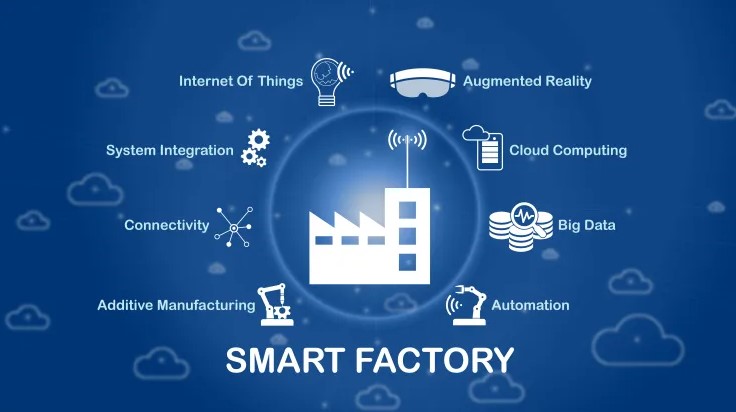

The manufacturing industry has witnessed significant changes in the past few years, thanks to the rapid evolution of technology. Smart Factory Automation has emerged as a game-changing technology, which has transformed the way factories operate. It leverages cutting-edge technologies like artificial intelligence (AI), Internet of Things (IoT), and robotics to create a self-learning system. It helps factories to reduce production costs, increase efficiency, and streamline the production process. In this post, we will explore the benefits of Smart Factory Automation and how it can revolutionize the manufacturing industry.

Smart Factory Automation offers several benefits, including increased productivity, better quality control, and enhanced safety measures. It eliminates the need for human intervention in routine tasks and helps factories to focus on more complex tasks. The use of robotics and AI ensures precision and accuracy in production, reducing the chances of errors and defects. It also reduces the risk of accidents, as dangerous and hazardous tasks are performed by machines, ensuring a safe working environment for employees. With Smart Factory Automation, factories can increase their production speed and volume, and meet the demands of their customers effectively.

Another advantage of Smart Factory Automation is that it enables real-time monitoring of the production process. The use of IoT sensors and other monitoring devices allows factories to collect real-time data about the production process, which can be analyzed and acted upon instantly. This real-time monitoring helps factories to identify any issues or bottlenecks in the production process, and take corrective measures before they escalate into bigger problems. It also helps factories to optimize their production process, making it more efficient and cost-effective. With Smart Factory Automation, factories can achieve higher levels of automation and digitization, which can improve their competitiveness in the market.

What is smart factory automation

Smart factory automation is a game changer for manufacturers who want to stay competitive in today’s market. With advanced automation technologies and intelligent systems, manufacturers can streamline production processes, improve efficiency, and reduce costs. Smart factory automation offers many benefits, making it a top choice for manufacturers looking to optimize their operations.

One of the primary benefits of smart factory automation is increased efficiency. By automating tasks, manufacturers can reduce the time it takes to complete tasks and improve accuracy. With smart automation, manufacturers can also run their production processes 24/7, which leads to a significant increase in output. This increased productivity can lead to faster turnaround times and better customer satisfaction.

Another benefit of smart factory automation is improved safety. Automation can eliminate many of the hazardous tasks that workers perform, reducing the risk of accidents and injuries. Automation can also provide real-time data that can be used to monitor equipment and identify potential safety issues before they become more serious. By implementing smart factory automation, manufacturers can create a safer work environment for their employees.

Benefits of smart factory automation

Improved Efficiency

Smart factory automation improves efficiency by reducing the likelihood of errors and minimizing production time. Automated systems operate faster and with greater accuracy, which results in less time required for production. Additionally, automated machines work continuously and require less maintenance, allowing for greater productivity and more output in the same amount of time. Overall, smart factory automation can significantly improve efficiency and output, resulting in increased profits for businesses.

Cost Reduction

By choosing smart factory automation, businesses can reduce costs associated with production. Automated systems reduce the need for manual labor, which in turn reduces the costs associated with salaries and benefits for employees. Additionally, automated machines require less maintenance and repair, which reduces the need for expensive repairs and maintenance. The result is a significant reduction in costs associated with production, resulting in increased profits for businesses.

Improved Safety

Smart factory automation provides a safer working environment for employees by reducing the need for manual labor and the potential for accidents. Automated machines can perform tasks that may be dangerous for humans, reducing the risk of injuries and accidents. Additionally, automated systems can monitor and detect potential hazards, such as machine malfunctions or environmental factors, allowing for quick intervention and preventative measures. Overall, smart factory automation can improve workplace safety and reduce the risk of accidents and injuries, resulting in a safer and more productive work environment.

Conclusion

The benefits of smart factory automation are clear, as it allows manufacturers to increase efficiency, reduce costs, and improve product quality. By incorporating advanced technologies like robotics, artificial intelligence, and the Internet of Things (IoT), manufacturers can streamline their production processes, optimize resource utilization, and minimize waste.

But beyond these tangible benefits, smart factory automation also offers intangible advantages, such as greater flexibility, adaptability, and responsiveness to market demands. With the ability to quickly reconfigure production lines and adjust production schedules, manufacturers can better meet changing customer needs and stay ahead of the competition.

Overall, the adoption of smart factory automation is essential for manufacturers looking to remain competitive in today’s fast-paced and rapidly evolving business landscape. By partnering with a trusted provider like PROS, manufacturers can unlock the full potential of smart factory automation and achieve their production goals with confidence.