Introduction

In the era of Industry 4.0, manufacturers have embraced a new way of producing goods that involves the integration of advanced technologies such as artificial intelligence, robotics, and the Internet of Things (IoT). This approach, commonly known as Smart Factory, has the potential to revolutionize the way we manufacture goods. It not only enhances efficiency and productivity but also ensures sustainability in the long run. With the continual technological advancements, Smart Factory Solutions have been made available, enabling businesses of any size from small to large corporations to leverage these technologies without necessarily investing billions of dollars in expensive systems.

Smart Factory Solutions have redefined the manufacturing industry, offering an opportunity to integrate all aspects of a business into one efficient and optimized process. Unlike the traditional factories that rely on manual labor, Smart Factories perform tasks automatically with the help of machines and computers. The adoption of Smart Factory Solutions results in streamlined processes, seamless communication between different departments, and minimal downtime. In addition, the technology provides enough data which businesses need to track and optimize their performance, ultimately leading to higher profitability.

The driving force behind Smart Factory Solutions is the desire to optimize processes and achieve maximum efficiency using the least amount of resources. The technology helps manufacturers to reduce the number of manual processes and, in turn, increases productivity. The computerization of the manufacturing processes ensures accuracy and reduced downtime due to human errors. The data gathered from these processes enable managers to track performance, identify inefficiencies, and make decisions that improve overall performance. Hence, Smart Factory Solutions have become an essential tool for manufacturers seeking to stay competitive in today’s fast-paced market.

What is smart factory

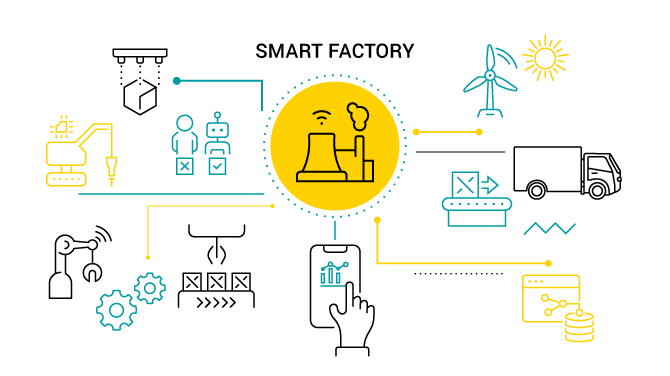

Industry 4.0 technologies offer smart factory solutions that enhance the efficiency, productivity, and profitability of manufacturing operations. These solutions incorporate the latest advancements in automation, data analytics, and connectivity to create a fully integrated and intelligent manufacturing environment. The smart factory concept is characterized by the use of cyber-physical systems, artificial intelligence, and the Internet of Things (IoT) to increase flexibility, reduce costs, and improve quality.

One of the key components of smart factory solutions is the integration of automation technologies, such as robotics, autonomous vehicles, and drones. These technologies are becoming increasingly prevalent in manufacturing facilities, as they allow for the automation of repetitive tasks and the reduction of labor costs. Additionally, the use of sensors and other IoT devices can help to monitor the performance of machinery, identify potential bottlenecks or issues, and optimize production processes in real-time.

Another important aspect of smart factory solutions is the use of data analytics tools to gain insights into manufacturing operations. This can include the collection of data from sensors and other sources, as well as the use of machine learning algorithms to analyze this data and identify patterns or trends. By leveraging these insights, manufacturers can make data-driven decisions to improve efficiency, reduce waste, and optimize production processes. Overall, the integration of Industry 4.0 technologies into manufacturing operations can provide significant benefits in terms of efficiency, productivity, and profitability.

Impact of smart factory

The fourth industrial revolution, Industry 4.0, has brought about significant changes in the manufacturing sector, particularly in smart factory solutions. Smart factories are factories that utilize advanced automation, robotics, and information technologies to facilitate production processes. Industry 4.0 technologies such as IoT, AI, and big data analytics have revolutionized smart factory solutions, enabling manufacturers to enhance their efficiency, productivity, and profitability. With IoT, smart factories can connect advanced machinery and devices, allowing real-time monitoring and analysis of production processes, leading to better decision-making and machine utilization.

Another significant impact of Industry 4.0 on smart factory solutions is the use of AI. AI allows machines to learn, adapt, and make decisions based on real-time data analysis. Smart machines, integrated with AI, can identify maintenance schedules, predict equipment failures, and prevent downtime, optimizing production processes and reducing losses. In addition, smart factories can use AI-powered robots for automated assembly, picking, and packaging tasks, significantly reducing operational costs while improving output.

The integration of big data analytics technology in smart manufacturing plants has also brought positive impacts. Big data analytics enable data from different sources to be collated and analyzed, providing manufacturers with valuable insights. Smart factories can use big data analytics to track inventory levels, measure the effectiveness of production plants, and monitor the performance of equipment, leading to informed decision-making and process optimization. Furthermore, big data analytics can aid in identifying opportunities for process improvement, helping manufacturers to increase efficiency and profitability.

Challenges

Industry 4.0 presents both significant challenges and opportunities for manufacturers. One of the main challenges is the high cost of implementing new technologies and infrastructure required for digital transformation. This includes investing in advanced analytics, IoT sensors, and robotics, as well as upgrading existing legacy systems. Moreover, Industry 4.0 requires a skilled workforce with expertise in operating and maintaining these systems, which may be in short supply.

However, Industry 4.0 also presents several opportunities for manufacturers. It enables them to create intelligent, connected, and efficient manufacturing ecosystems that can significantly improve productivity, reduce costs, and create new business models. By leveraging real-time data analytics and machine learning algorithms, manufacturers can optimize their operations, reduce downtime, and improve quality control.

In addition, Industry 4.0 enables manufacturers to create new revenue streams through the use of innovative technologies such as 3D printing, augmented reality, and blockchain. For example, 3D printing can enable manufacturers to produce parts on-demand, reducing the need for expensive inventory and supply chain management. Augmented reality can help streamline the manufacturing process by providing real-time data and remote support to workers on the factory floor. Finally, blockchain technology can help manufacturers improve supply chain transparency and traceability, which can be critical in industries such as aerospace and defense.

Overall, while there are significant challenges associated with implementing Industry 4.0, the potential benefits are substantial and can enable manufacturers to transform their businesses and gain a competitive advantage in the global marketplace.

Conclusion

In conclusion, smart factories are revolutionizing the manufacturing industry by creating a more efficient, flexible, and connected manufacturing process. With the introduction of advanced technologies like IoT, AI, and automation, smart factories can improve production quality, reduce waste, increase productivity, and lower costs. Nevertheless, to fully realize the benefits of smart factories, companies need to invest in digital transformation, create a culture of innovation, and adopt new business models that embrace the changing landscape of manufacturing. By doing so, companies can position themselves as leaders in the industry, withstand disruption, and achieve long-term success.